Comparing China’s Leading Lighting Solutions: A Guide for Buyers of “led strip lights supplier” & “led module manufacturer”

Lighting has come a long way from conventional bulbs. Today, professionals and buyers in industries like interior design, signage, automotive, and retail are turning to LED-based solutions for better efficiency, durability, and design flexibility. Whether you’re outfitting a retail store or working on a large-scale signage project, understanding what to expect from a led strip lights supplier and a led module manufacturer can shape your decision.

This article breaks down both solutions, helping you compare core differences, real-world uses, and buying tips without the sales pitch.

The Role of a LED Strip Lights Supplier

LED strip lights have earned their popularity because they’re slim, adaptable, and can be installed virtually anywhere. A led strip lights supplier typically focuses on delivering a range of flexible lighting solutions that can be cut to length, come in waterproof variants, and support different voltages like 12V, 24V, or even 220V.

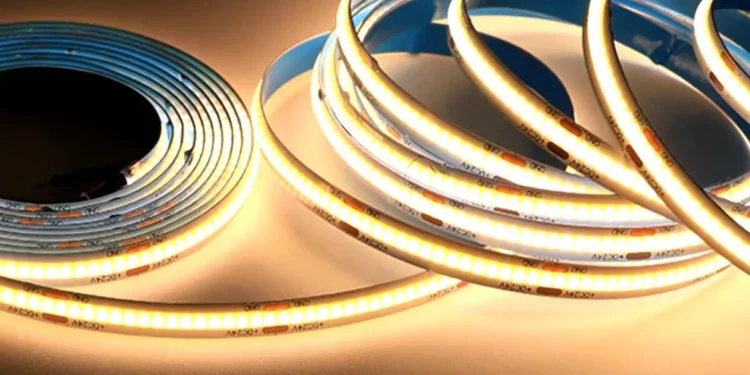

When you’re choosing a supplier, you’re not just buying a product, you’re sourcing consistency. Suppliers often stock options like SMD and COB strips, offering high-density chip layouts that balance brightness with energy efficiency. For applications like under-cabinet lighting, architectural accents, or ambient lighting in commercial spaces, these strips provide the kind of flexibility designers and engineers look for.

Quality is key. A reliable supplier should clearly list specs like lumens per meter, color temperature, and IP ratings. Compliance with standards like CE, RoHS, or FCC isn’t just a formality; it speaks to safety, especially when lighting is installed in moisture-prone areas or outdoors.

What Makes an Effective LED Module Manufacturer?

While strip lights are known for versatility and ambiance, LED modules are the unsung heroes of structured lighting. A led module manufacturer builds more rigid, purpose-specific lighting components usually encased in waterproof housings and designed for use in signage, channel letters, or exterior wall accents.

LED modules often come in rectangular or bullet-shaped formats, incorporating two to four LED chips per unit. These chips are usually SMD-based, but unlike strip lights, modules are spaced apart and often have optical lenses to control beam direction. Manufacturers offer waterproof grades like IP65, IP67, or IP68 useful for long-term outdoor durability.

A good manufacturer pays close attention to thermal regulation, driver compatibility, and chip consistency. Modules are expected to last over 50,000 hours and must maintain even brightness across all units in a system especially when spelling out logos or running continuously on storefronts.

If you’re working on a project that requires backlighting acrylic letters or creating standout signage that competes in daylight, LED modules offer both brightness and rugged build quality.

Comparing Features Side by Side

Here’s how LED strip lights and modules differ across several factors:

| Feature | LED Strip Lights Supplier | LED Module Manufacturer |

| Flexibility | High – bendable and cuttable | Limited – fixed shapes |

| Best For | Interior accents, coves, displays | Channel letters, signage, facades |

| Voltage Options | 12V / 24V / 220V | Mostly 12V |

| Durability | Optional IP ratings | Typically IP68 or higher |

| Customization | Length, color, CRI, voltage | Lens angle, spacing, mounting design |

| Installation | Peel-and-stick or aluminum channels | Mounted with screws or clips |

Each type of product serves a unique purpose. A project demanding subtle ambient light or decorative flexibility will benefit from a strip light system. On the other hand, when the goal is direct, structured, and waterproof lighting, modules are the right tool for the job.

Key Considerations When Choosing a Supplier or Manufacturer

No matter which lighting type you’re sourcing, here are some important factors to consider:

- Product testing: Are photometric reports or aging test results available?

- Certifications: Look for CE, RoHS, or FCC marks as a baseline.

- Component quality: Ask about chip brands (e.g., Epistar, Osram) and thermal pad materials.

- Packaging & logistics: Consistent batch labeling and safe delivery are often overlooked but crucial.

- Support: Does the company offer datasheets, CAD files, or wiring guides?

Interestingly, many companies operate as both suppliers and manufacturers, especially in regions like Shenzhen or Dongguan. While that can be efficient, it’s worth checking whether a single brand is actually producing in-house or simply reselling.

FAQ

Q: What’s the main difference between LED strips and LED modules?

A: LED strips are continuous, flexible circuits suited for decorative or low-profile lighting, while modules are individually sealed units used for high-brightness or outdoor signage applications.

Q: Can I use LED modules for indoor lighting?

A: Yes, though it depends on the project. Modules are more directional and rigid, so they’re typically used where bright and focused light is needed.

Q: Are COB strips better than SMD?

A: COB (Chip on Board) strips offer a more uniform light with fewer visible dots, ideal for areas where aesthetics matter. SMD strips provide better brightness control and easier repairs.

Q: What voltage is ideal for commercial use?

A: 24V is common for longer LED runs due to reduced voltage drop, while 12V suits shorter, simpler installs. Modules typically standardize around 12V.

Final Thoughts

LED lighting continues to evolve, offering more choices and configurations than ever before. Whether you’re sourcing from a led strip lights supplier or working directly with a led module manufacturer, your decision should align with the technical demands of your project: durability, brightness, design, and control.

By understanding the fundamental strengths of each, buyers can make more informed choices and avoid costly mistakes when installation time rolls around.